CGET, a 20-year internationally-known brand for brewing equipment and package line.

Chemical Beverage Beer Filling Machine Beer Keg Washing Beer Canning System

This machine characteristics :

This machine is designed for the washing sterilizing and filling work of all kinds of beer refreshing containers ( including stainless steel refreshing keg and draught beer keg ) . And this machine can do the works washing , sterlizing filling and CO2 pressure preparing automatically .

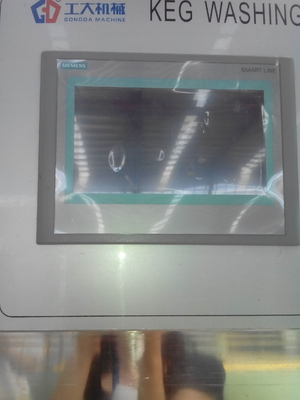

The control unit of this machine uses the Mitsubishi Programmable controller and WEINVIEW human-computer interface . All of the controls parameters ( time value ) can be adjusted when it is running . This machine is easy to operate . Simple and reliable!

This machine is electricity saving and water saving type , it can save 50% water .

1. Technical parameter

1.1 Specification and size and main technical parameter :

Worktable size(mm): 525x1140

Worktable height(mm): 660

Machine outside measurement(mm): 1200*1500*1945

Piston maximum stroke(mm): 300

Net weight(Kg): 245

Ability : 10-20kegs/hour

Air consumption: 8 - 22.5m3/hour(10L keg)

Water consumption:0.5 - 2 m3/hour(10L keg)

Power: 1100W

Washing style: Inverted washing

Kegs’ size(mm):Diameter:ф250-500

Height:400-660 mm

:

1.2 Technical requirements :

Air pressure: 0.6 - 0.8Mpa

Cylinder pressure: 0.4 - 0.5Mpa

CO2 pressure: 0.2 - 0.3Mpa

Steam pressure: 0.15 - 0.2Mpa

Hot alkaline water temperature: 40-80℃

Hot water temperature: 40-80℃

Oxyful consistency: 0.5%

Alkaline water consistency: 1.5%

Electric source pressure: AC50Hz 220V

2.Primary structure :

Plastic keg cleaning head Stainless steel keg vleaning head

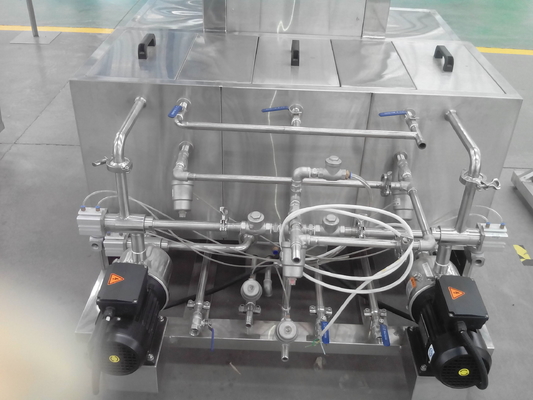

This machine is made up of stander , electric control casing , solenoid valve , pneumatic element , air blast system and water flow system etc. parts . There are two kinds of cleaning heads , one is used for cleaning stainless steel kegs , the other one is used for cleaning plastic kegs .

3.Working routine :

The control unit of this machine uses the Mitsubishi Programmable controller and WEINVIEW human-computer interface . All of the controls parameters ( time value ) can be adjusted when it is running . This machine is easy to operate . Simple and reliable!

3.2 Stainless steel keg washer setting :

Compress→ →clean with clean water→ →clean with hot alkaline

water→air blast(recycle to alkaline water tank)→clean with hot water→air blast(to clean water tank)

→steam sterilize→steam pressure maintaining→clean with sterile water→ →CO2

preparing pressure→cylinder restoration

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!