304 Stainless Steel Glass Bottle Filling Machine 220V Or 380V Voltage

- Equipment Introduction

Beer Bottling Tri-block Machine 3-1 unit machine is a washing filling capping 3 in 1 machine designed combined with the actual situation in our country after the introduction and absorption. It adopts the bottle filling and capping technique of Germany technology. It has been specially used to fill Beer.

It adopts isobaric filling principle and filling valve adopts high precision mechanical valve. It has advantages of fast filling speed, high precision in liquid level. Adopt Siemens automatic controlling system, realizing trinity of the machines, and control the washing, filling and capping process and realize that it only starts to filling when there is a bottle, otherwise it will stop filling and no broken bottles. The filling process is cleaner and pure due to it’s twice vacuumization of bottles, and more stable because of isobaric filling operation. Using vacuum pump and CO2 preparing pressure to realize a second vacuum, ensure no air and bacteria in the bottle, guarantee the filling quality and warranty quality time. Filling cylinder braces use worm-gear box going up and down to satisfy bottles of different height. Float switches in the filling cylinder ensure a smooth liquid inlet. Therefore, this machine is the best ideal choice for Beer factories.

(2)Equipment composition

The main properties of machine: rational design, easy operation, safety device, plate easy cleaning, the height is adjustable. The machine can be divided into six parts: a. filling machine b. Operation platform c. capper d. bottle transmission part e. pipe system: liquor level control, liquid main pipe

Composition of washing part

Washing machine is made up of lifting device, the main transmission device, the fixed frame, clamp device, distributor, open clamp cams and over turn cams, etc.

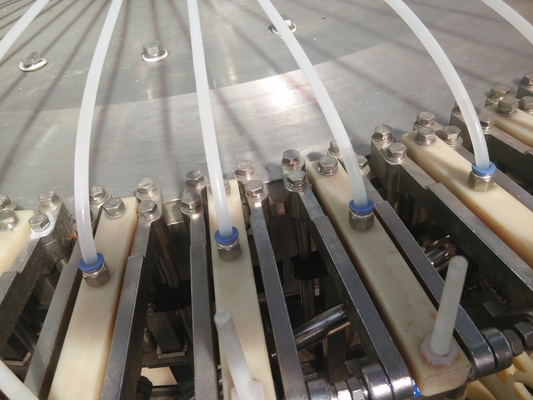

Composition of filling part

Filling machine are made up of liquor pipe, rotating cylinder bearing base, filling cylinder fulcrum loop, filling cylinder, filling valve, filling cylinder pipe, control loop device, ascending device, the distributor, height adjusting control, cleaning glass, stimulating bubble arm, vacuum system, etc.

Slick Beer tank inside after special polishing.

No dead angle for Beer retention. Easy for clean .

High accuracy mechanical filling valve

Composition of capping part

The capping machine is composed of hopper, slide rail, top-cap part, lifter, and turn-stop column.

Technology data:

| Filler Block |

| No. |

|

1 |

| Make |

|

CGET |

| Capacity |

bph |

12000-15000 |

| Max/min diameter of containers to be handled |

mm |

Φ50~Φ85mm |

| Max/min height of containers to be handled |

mm |

150~300mm |

| Machine efficiency at full speed |

% |

>98,5 |

| Rinsing time at full load |

sec |

2-3 |

| Dripping time at full load |

sec |

1-2 |

| Number of rinsing grippers |

|

50 |

| No bottle - no rinsing function |

|

Yes |

| Sterile filter for rinsing medium |

|

Yes |

| Rinsing medium |

|

Water |

| Rinsing medium consumption |

l/h |

600~1200 |

| Filling temperature |

°C |

0-4 |

| CO2 content |

g/l |

4-7.5 |

| Number of filling heads |

|

50 |

| No bottle - no filling function |

|

Yes |

| Maximum DO pickup over the filling process |

mg/l |

≤100ppb |

| High pressure water injection |

|

Yes |

| Heater for injection water |

|

Yes |

| Number of crowning elements |

|

12 |

| No bottle - no crown function |

|

Yes |

| Crown cap - diameter |

mm |

26 |

| Shower after crowner |

|

Yes |

| Length |

mm |

5050 |

| Width |

mm |

4100 |

| Height |

mm |

2750 |

| Weight (emtpy / in operation) |

kg |

8500 |

| Installed power |

kw |

10.8KW |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!